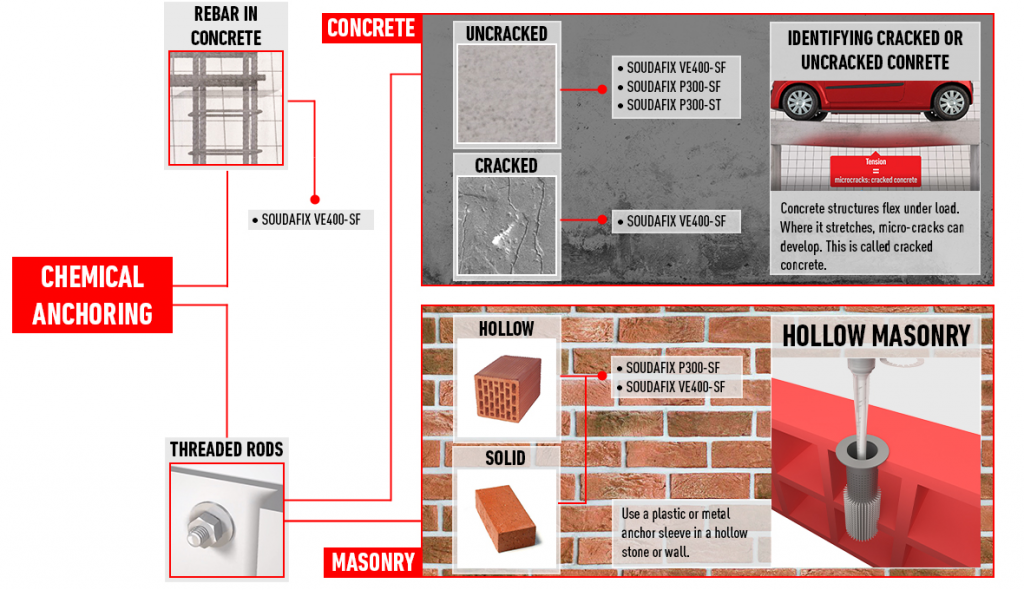

Chemical Anchoring is a technique used to improve the load capacity, flexibility and durability of an installation. Through adjusting the anchoring depth, Soudafix chemical anchors offer the flexibility to adapt the load capacity according to requirements of the application onsite. There is no damage to the substrate as chemical anchors do not expand after application, meaning no additional stress to the surrounding surface or hole.

The Soudafix professional chemical anchor resins offer comprehensive fixing solutions for most applications and substrates. Anchors can be fixed in cracked and uncracked concrete, solid and hollow masonry. Soudafix products are ETA certified (European Technical Assessment) which guarantees you a reliable installation.

As an installer, you need anchoring solutions that you can rely on unconditionally. Which is why it is important to select the correct Soudafix chemical anchor for the application.

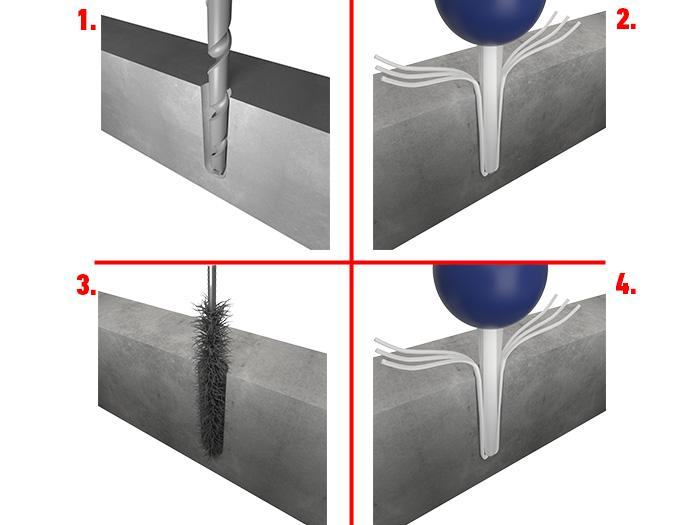

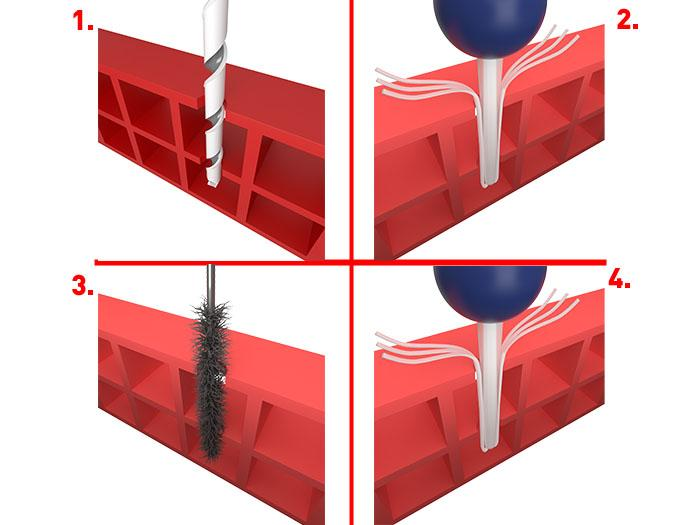

To guarentee the full tensile and shear strength of the Soudafix products, it is extremely important that the installation is carried out correctly. Skipping or careless execuriong of one of the steps can reduce the anchoring strength by factor of ten.

Drill the hole to proper depth and diameter per specifications using a rotary hammer drill with a stop drill bit.

Clean the hole using a blow-out bulb, pump or compressed air.

Clean the hole using a wire brush to ensure no loose debris remains in the hole.

Clean the hole again using the blow-out bulb, pump or compressed air.

Drill the hole to a proper depth and diameter per specifications using a rotary hammer drill with a stop drill bit.

Clean the hole using a blow-out bulb, pump or compressed air.

Clean the hole using a wire brush to ensure no loose debris remains in the hole.

Clean the hole again using a blow-out bulb, pump or compressed air.

Insert Anchor Sleeve into the hole.

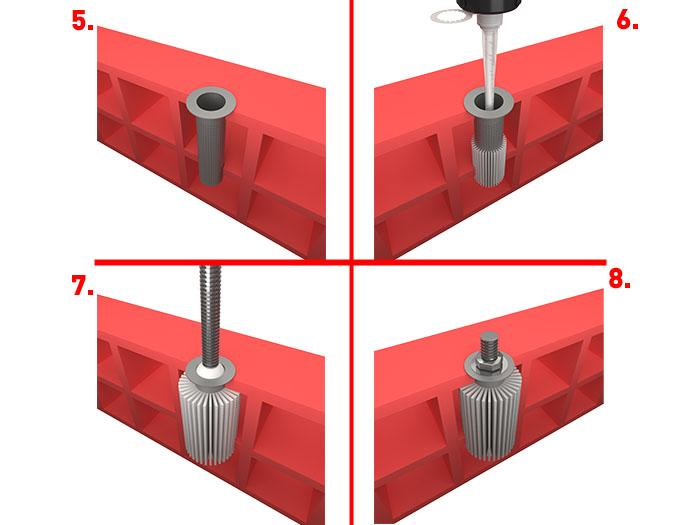

Apply the Soudafix chemical anchor resin into the sleeve, ensuring the resin is mixing properly before application.

Push and turn the threaded rod into the hole containing the Soudafix chemical anchor resin.

Fix the nut onto the thread, but only after full curing.