In train and coach manufacturing, direct glazing involves bonding glass windows directly to the vehicle structure without need for traditional mechanical fasteners. This method ensures improved aerodynamics, enhanced aesthetic appeal, and better durability, as it eliminates gaps and reduces air or water leakage. Soudal has long been providing adhesive and sealant solutions tailed to rail, OEM, and sub-supplier assembly lines, ensuring strong, flexible, and weather-resistant bonds.

Panel Bonding , Structural Bonding, Luggage & Door Assembly, Moulding & Trim Finishing

Rail vehicle manufacturers encounter unique challenges in designing and assembling exterior components such as roof and mask systems. These components must withstand high speeds, harsh environmental conditions, and the aerodynamic stress composed during operation. Selecting the appropriate adhesive solution is crucial to ensure the durability and safety of these systems.

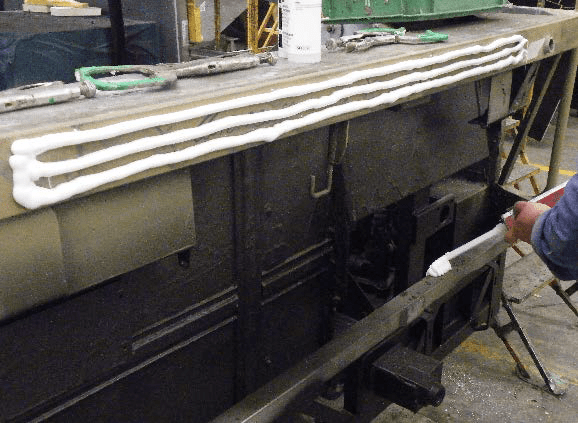

Seam Sealing

Modern rail vehicle interiors need high durability and service life expectancy in order to meet the day-to-day requirements of transporting large numbers of people in comfort and safety. Rail vehicle operators demand high performance and reliability from their rolling stock to reduce down time and remain competitive.

Cosmetic Finishing

The finish and integrity of a rail vehicle is crucial to its long-term durability. A robust, watertight seal protects sensitive components such as wiring looms, vital electronic equipment and other systems situated beneath the floor and behind interior panels.

Modern rail vehicles require the use of a number of high performance flooring materials during manufacturing to ensure travelling comfort, lower vibration and better sound damping in service. Soudal has formulated a range of elastic solutions for floor bonding that enable these and other benefits to be delivered to the customer.